Nylon brush strips are an ideal choice in the field of wide line manufacturing in PCB manufacturing, such as line width/line spacing > 200um (8mil), copper foil thickness ≥ 35um, and sometimes can be relaxed to > 150um (= 6mil) . Due to its particularly high resilience, the nylon strip brush will not damage the brush roller when the PCB board is warped or the drill bit is broken, and the brush roller will not be damaged if the operator makes mistakes such as forgetting to turn on the cooling water. Stabilize and brush the circuit board and brush roller. Next, Aoqun Brush Industry will introduce the role of nylon strip brushes in PCB manufacturing. 1. Deburring process after drilling, when the burr is larger than 75um, choose the following combination: 180# silicon carbide and 240# silicon carbide 2. In the deburring process after drilling, when the burr is larger than 50um, the following combination should be selected: 240# silicon carbide and 320# silicon carbide. 3. In the deburring process after drilling, when the burr is less than 50um, choose the following combination: 320# silicon carbide and 320# silicon carbide. 4. For pretreatment of photosensitive film, choose the following combination: 320# silicon carbide and 500# silicon carbide. 5. After PTH treatment, choose the following combination: 320# silicon carbide and 320# silicon carbide. 6. For pre-treatment of green oil (solder resist) coating, choose the following combination: 500# silicon carbide and 500# silicon carbide. 7. For the pre-treatment of the gold plate (including gold fingers), the following combination is selected: 800# alumina and 1000# alumina. 8. For the volcanic ash grinding machine, 6pcs of pure nylon spring brushes are used. 9. For flexible plate grinding, choose the following combination: 600# alumina and 1000# alumina.

read more

The material selection of industrial brushes is very important to the service life of industrial brushes and the effects of polishing, dust removal, surface treatment, etc., so the main materials generally used are steel wire, copper wire, stainless steel wire, nylon wire, plastic wire, abrasive wire, horsetail hair , bristle, sisal and so on. There are many industrial brush products, the simple classification is as follows: brush roller, wire brush, strip brush, belt brush, disc brush, spring brush, nylon brush, rubber roller, sponge absorbent roller, sanitation Car sweeping brush, fireplace chimney brush, bottle washing brush pipe brush, fruit and vegetable cleaning machine brush roller, textile printing and dyeing industry brush, ceramic glaze line brush, glass cleaning machine brush roller, paper printing equipment rubber roller, anti-static Brushes, metal polishing abrasive brushes, metal pickling brush rollers, automatic shoe polisher brush wheels, etc., and other special brushes. 1. Nylon roller brush: brush body nylon 6 or 66, nylon bristles 1010 Specifications: brush body diameter φ30-φ500mm, hair length arbitrary, bristle wire diameter φ0.10-φ1.0 2. Stainless steel roller brush: brush body stainless steel, bristle stainless steel wire Specifications: φ50-φ500mm, arbitrary hair length, bristle wire diameter φ0.10-φ1.0 3. Nylon spiral roller brush: brush body nylon 6 or 66, nylon bristles 1010 Specifications: The diameter of the brush body is φ20-φ500mm, the length of the bristles is arbitrary, and the diameter of the bristles is φ0.10-φ1.0. The angle width can be made according to the drawing. 4. Stainless steel spiral roller brush: brush body stainless steel, bristle stainless steel wire Specifications: φ30-φ500mm, arbitrary hair length, bristle wire diameter φ0.10-φ1.0. The angle width can be made according to the drawing. 5. Nylon roller brush: brush body nylon 6 or 66, nylon bristles 1010 Specifications: brush body diameter φ60-φ500mm, hair length arbitrary, bristle wire diameter φ0.3-φ1.0 6. Nylon board brush: brush body nylon 6 or PVC, nylon bristles 1010 Specifications: The width of the brush body is 8-300mm, the length of the bristles is arbitrary, the diameter of the bristles is φ0.10-φ1.0mm, and the length is arbitrary. 7. Stainless steel disc brush: brush body stainless steel, bristle stainless steel wire Specifications: The diameter of the brush body is φ100-φ500mm, the thickness of the brush body is 10-30mm, the length of the bristles is arbitrary, and the diameter of the bristles is φ0.5-φ1.2mm.

read more

"Professional, refined, special and new" enterprises refer to the four major advantages of specialization, refinement, specialization, and novelty, in line with the "Industrial "Six Bases" Development Catalog", strategic key industries for manufacturing power, strategic emerging industries, and high-quality manufacturing Develop pillar industries and other fields with outstanding main business, strong competitiveness, good growth, advanced and exemplary enterprises in the industry. "Professional" Of Aoqun Brush Company Aoqun Brush Industry is a brush high-tech enterprise integrating production, research, supply and marketing. Its core product matrix covers environmental cleaning, automobiles, medical health, new energy, rail transit, smart home and wearables, 5G communications, etc. Key industries planned during the 14th Five-Year Plan period. Focusing on the main business and rooted development, the company adheres to the brand concept of "focusing on quality and embodying value", insists on innovation as the center and customer demand as the guide, and is committed to providing customers with high-performance brushes such as strip brushes, twisted wire brushes, and planting brushes. Product solutions, on the basis of taking the lead in formulating corporate standards, the formulation of leading product group standards and industry standards and the certification of the integration of industrialization and industrialization have been implemented. The "Fine" Of Aoqun Brush Company AOQUN has always implemented the quality policy of "Adhering to scientific management, pursuing excellent quality, continuous and effective improvement, and enhancing customer satisfaction", integrating the concept of lean production and management thinking into the entire production process of products, and has obtained high-tech enterprise, IATF16949, ISO13485, ISO90001 quality Certification and honorary titles such as management system, intellectual property rights and integration of industrialization and industrialization, production safety standardization enterprise, contract-abiding and credit-abiding, tax credit A-level, and innovative small and medium-sized enterprises. The "Special" Of Aoqun Brush Company The company has been carrying out quality control in strict accordance with the corresponding inspection standards, pays close attention to details in the 39 production processes of each brush, stimulates management innovation vitality, promotes quality and efficiency improvement, continuously optimizes product design and process flow, and realizes more efficient product processing. "Precision", "Efficiency" and "Personalization"; at the same time, cooperate with many universities to carry out industry-university-research cooperation, provide brush spare parts for well-known enterprises and major projects in more than 20 industries, and have been widely used in the industrial chain and supply chain. Key links and key areas play the role of forging long boards,...

read more

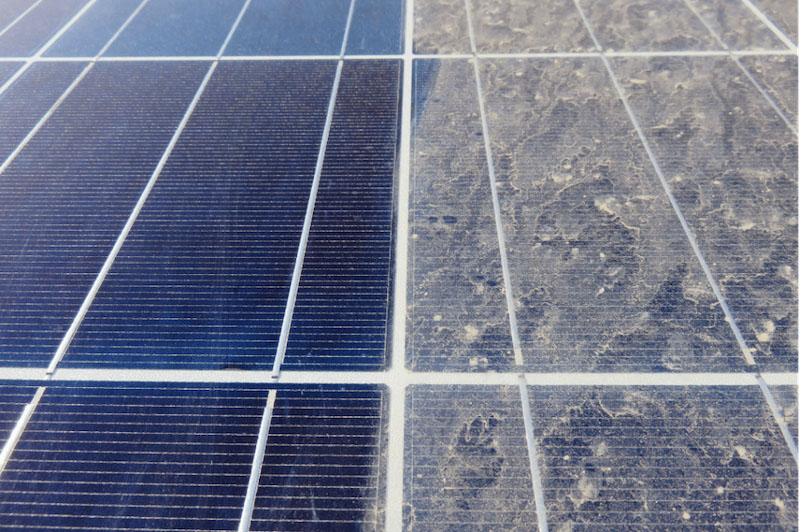

After the photovoltaic system is installed, the user is most concerned about the power generation, because it is directly related to the user's return on investment. There are many factors that affect the power generation, such as the quality of components, inverters, cables, installation orientation azimuth, inclination angle, dust, shadow occlusion, system scheme for component and inverter ratio, line design, construction, grid voltage, etc. factors are possible. The most common types of pollution solar photovoltaic panels are the following: Components affected by dust. The dust on the surface of the panel has the functions of reflecting, scattering and absorbing solar radiation, which can reduce the transmittance of the sun, resulting in a decrease in the solar radiation received by the panel and a decrease in output power. 1. The influence of temperature, with the accumulation of dust on the surface of the module, the heat transfer resistance of the photovoltaic module is increased, and it becomes the heat insulation layer on the photovoltaic module, which affects its heat dissipation. 2. Blocking effect, dust adheres to the surface of the battery panel, which will block the light, absorb and reflect the light. Compared with the dusty components, the output power of the clean battery panel components is at least 5% higher. 3. The surface of photovoltaic panels is mostly made of glass. When wet acidic or alkaline dust is attached to the surface of the glass cover, the glass surface will be slowly eroded. Photovoltaic panels are very fragile and cannot be cleaned with hard objects. They cannot be stepped on solar panels, brackets and other parts. They are easy to damage the power station and affect the service life. Therefore, use a fully automatic cleaning machine equipped with solar panel cleaning brushes. , is the best cleaning tool. The solar cleaning brush installed in the cleaning machine is made of thousands of filaments, which will not damage the solar photovoltaic panels.

read more

Please note that our company will be closed for the Chinese New Year celebration from 15th, Jan until 28th, Jan . Normal business will resume on 29th, Jan.

read more

One of the leading and reliable sources of energy is solar energy. It has become very popular and as the demand for this industry is growing. Some of the reasons why it is good to go for solar include low maintenance cost, does not require much space to function, pollution-free and they can work on their own. Every building with roofs will have the opportunity to install solar panels to produce power and reduce carbon emissions. After the panels have been installed, they usually require little maintenance to function. In order to make the most out of the investment, it is important to make sure that the solar panels function at their best to maximize energy savings. Is It Necessary To Clean Solar Panels? Generally, most solar panels are self-clean as they are installed at an angle so rainfalls can give the panels a good washing. On the other hand, if the area where the panels are installed does not receive a lot of rain or if they are installed near factories, airports, the coast or highways, regular cleaning is important because these places generate more dust and dirt. Bird droppings or stubborn dirt can obstruct sunlight and this will affect the performance of the solar panel systems. Cleaning the solar panels is pivotal for them to function at their optimal capacity all year round. Increase Efficiency Solar panels that are clean will deliver a much higher energy strength than uncleaned panels. When dirt, dust and bird droppings accumulate on the panel glass, they will decrease the amount of sunlight being absorbed. When they are not receiving enough sunlight, the solar panels will not be able to perform at maximum capacity. This may lead to an increase in cost when the system has to rely on the grid to make up for the panels’ inefficiency. Solar PV Panel Cleaning Brushes Protecting Investment Solar panels are a big investment. Regular cleaning of the solar panel system with the right photovoltaic panel cleaning brushes will help to extend its lifespan and improve efficiency in producing electricity. Taking care of the panels to ensure that they are clean will not only help them to increase productivity but also ensure that they do not degrade faster than they should. Ultimately, regular cleaning using high-quality cleaning brushes from Aoqun, a leading solar panel cleaning brushes manufacturer will ensure the most return on the investment. Debris and dirt are unavoidable threats to the production of solar energy, especially for solar plants located in dusty areas. This can cost millions of dollars to be lost. Therefore, it should be the main priority for providers to minimize overall costs and maximize efficiency by cleaning the panels regularly.

read morescan to wechat

scan to wechat