From 5G Base Stations to New Energy Vehicle Electronics

As the "nerve center" of electronic devices, PCB are witnessing surging global demand. Traditional cleaning methods – inefficient and environmentally harmful – have become critical bottlenecks for industry advancement.

Aoqun Brush breaks through barriers with innovation, delivering high-efficiency polishing and cleaning solutions for PCB, empowering high-quality manufacturing in electronics, and propelling industrial excellence.

The Efficiency Dilemma

Manual cleaning wastes time and labor; chemical cleaning incurs high costs and safety risks.

The Environmental Crisis

Traditional cleaning agents contain hazardous substances, threatening ecosystems and human health.

Aoqun Brush leverages cutting-edge "high-precision" technologies, supported by its Engineering R&D Center and a 20-year expert team, to craft intelligent high-performance PCB abrasive brushes.

1. Responsive service | Global bulk delivery with guaranteed quality

2. 1-day solution design | 3-day customized prototyping | 7-day mass production

3. Annual capacity: 250 million units – driving industrial upgrades with precision-engineered solution

Aoqun Core Advantages

Efficiency Redefined

Achieves precision cleaning for holes as small as 1mm, boosting cleaning efficiency by 50%+.

Green & Safe

Certified to UL94-V0, EN45545, ROHS, SVHC, and 30+ international standards for environmental safety.

Durability & Cost-Effectiveness

Withstands 1 million+ high-frequency friction cycles, resists heat/abrasion/corrosion, extending lifespan by 30%.

Customized Excellence

Density up to 300,000 filaments/m², enhancing cleaning precision across diverse PCB materials and processes.

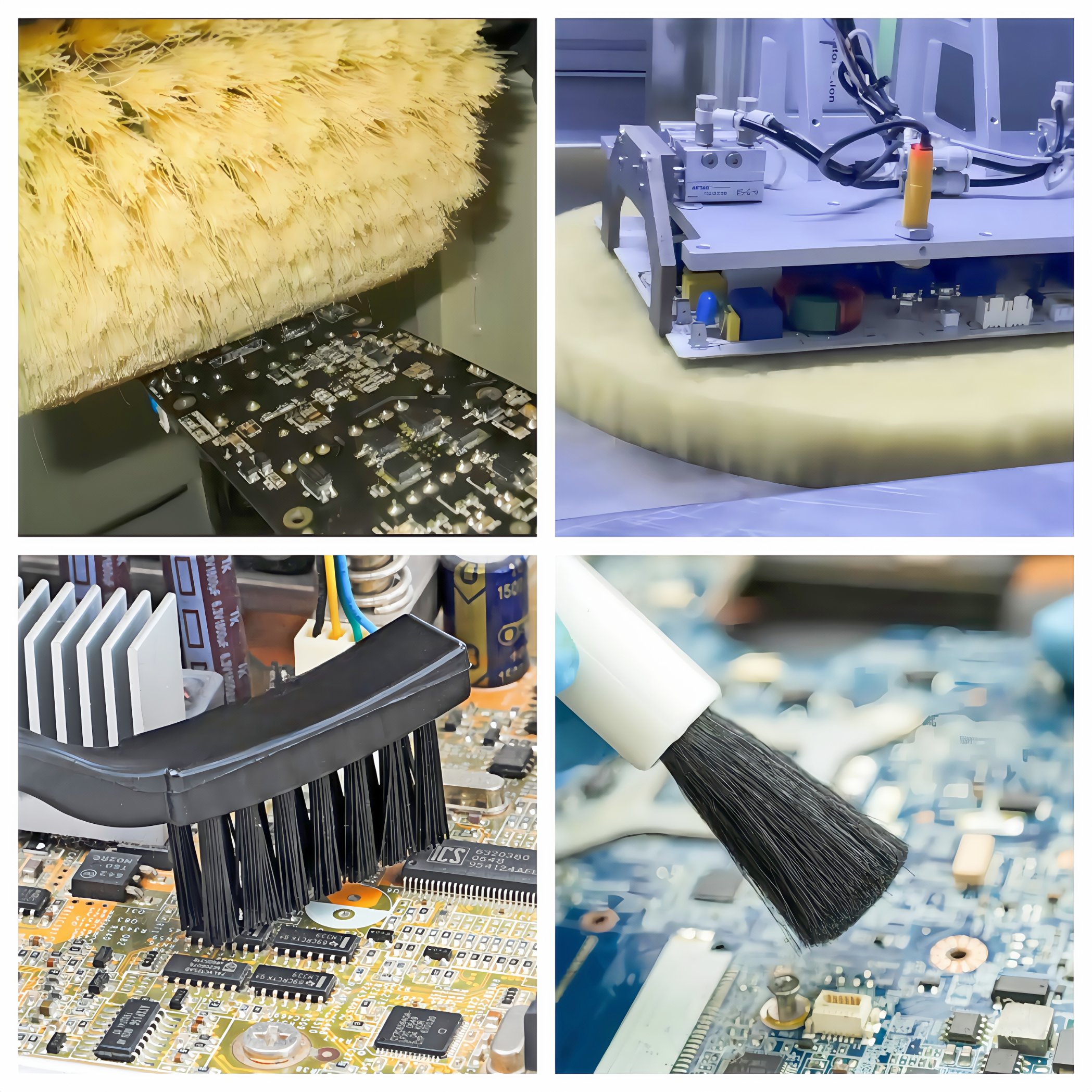

Aoqun’s high-performance brushes are deployed across PCB manufacturing stages:

1. Drilling deburring

2. Pre-copper deposition cleaning

3. Pre-patterning cleaning

4. Pre-solder mask cleaning

5. Surface treatment preparation

Results:

1. 15% increase in product yield

2. 20% boost in production efficiency

3. Enhanced circuit board cleanliness, welding quality, and electrical stability

Aoqun remains committed to innovation-driven growth, advancing high-quality productivity in 3C electronics manufacturing and injecting green momentum into global electronics industries.

- END -

About Aoqun Brush Industry

A pioneer in intelligent brush manufacturing and digital-core technologies.

1. National High-Tech Enterprise & Specialized and Sophisticated SME

2. Integrated R&D-Production-SupplyChain-Quality ecosystem

3. Formulated 8 industry/group standards | Contributed to 1 national standard

4. 101 IP achievements (20 invention patents + 2 international patents)

5. Certified to IATF16949, ISO13485, ISO9001, ISO45001, ISO14001

6. Tier-1 supplier to 20 Fortune Global 500 firms including CRRC, BYD, Hitachi, Miele

scan to wechat

scan to wechat