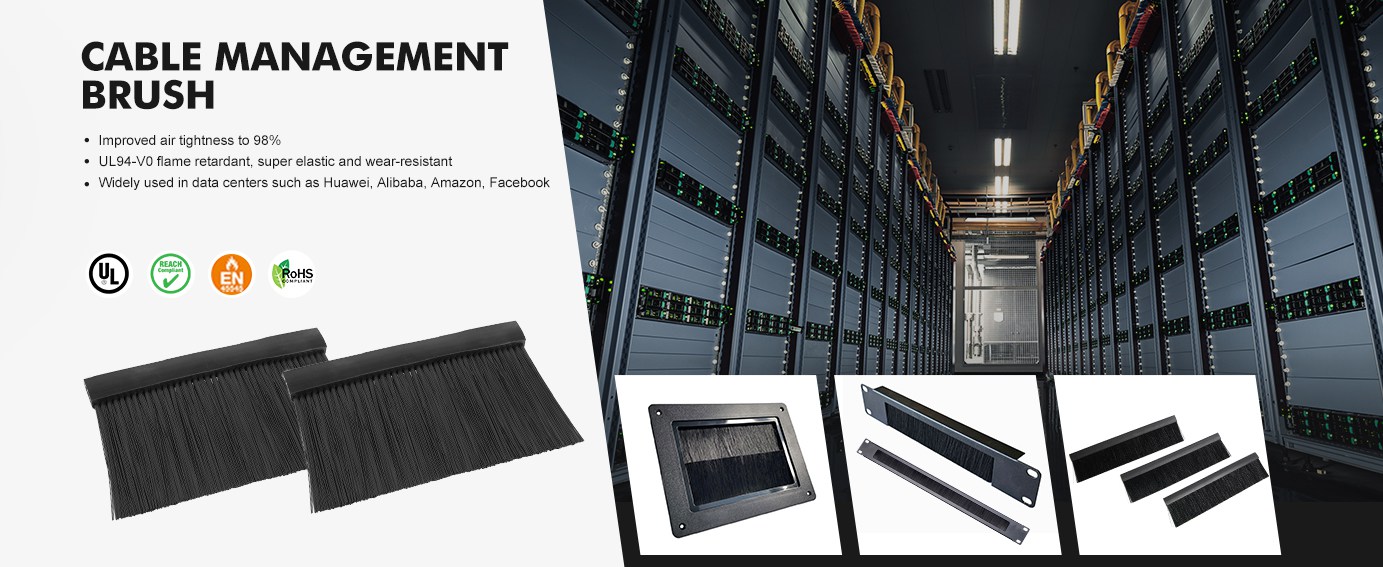

5G communication Aoqun showcases at the Canton Fair to promote the export of cabinet brushes, highlighting the "new" power of manufacturing Innovative Canton Fair, connecting the world. The countdown to the 136th Autumn China Import and Export Fair (Canton Fair) is in progress! This Canton Fair brings together new products, new technologies, and new information from all industries around the world, opening up the supply and demand chain more directly and efficiently, effectively shaping new advantages in foreign trade competition, and enhancing the core competitiveness of the industry. As a benchmark in the global brush field, Aoqun Technology once again made a stunning appearance at the Canton Fair with a number of heavyweight 5G communication special brush new products. With new products, new technologies, new services, and new experiences, it has demonstrated the charm of "Aoqun Smart Manufacturing" to global merchants and provided professional, digital, and characteristic brush customization solutions, using practical actions to practice new quality productivity and help 5G communication! -Invitation Letter-- Highlights preview 01 UL94-V0 flame retardant grade AOQUN cabinet inlet brush has reached the highest UL94-V0 flame retardant grade, specially designed for data center environment to meet key requirements such as flame retardancy, sealing, and adaptability, and help 5G communication! 02 EU multi-country authoritative certification AOQUN's patented cabinet inlet brush has passed 30+ European and American authoritative certifications, export quality, sealed dustproof, anti-static or flame retardant materials, all-round protection of your equipment, improve work efficiency. 03 Compatible with various cabinet installations This cabinet brush has strong adaptability and is compatible with various cabinet installations. No matter what type of cabinet, it can be easily matched and installed simply and quickly; among them, double-layer installation has strong sealing, effective dustproof, and keeps the equipment running clean and stable. 04 Assist 5G communication This brush that data center IDC really needs has been successfully used in Schneider, Huawei, Alibaba, Amazon, JD.com, Facebook, Apple and other well-known corporate data centers, and its quality and service have been widely recognized. About Aoqun Technology Aoqun Technology has been focusing on the research, production, supply and marketing of high-quality brushes for 20 years. It has been awarded the title of National High-tech and Provincial Specialized New Enterprise. It is committed to providing customers with a full range, full scene, high-performance, high-precision one-stop high-end brush solution. It has provided high-quality brush mass customization and related supporting products for more than 30 leading companies in industries such as high-speed rail, medical, smart home, automobile, photovoltaic, etc. It is a core supplier of 20 Fortune 500 companies such as CRRC, BYD, Hi...

read more

Rail transit, airports and ports high elastic and wear-resistant sealing brushes At the 136th Autumn Canton Fair, Aoqun's innovative rail sealing brushes made a grand debut Connecting and integrating innovation, opening up a new quality future. The countdown to the 136th Autumn Canton Fair is underway. Innovation is one of the most distinctive features of this Canton Fair. Innovative design in all fields and zero outdated models are 100% innovation-led development; the products on display are more cutting-edge and innovative. As a benchmark in the global brush field, Aoqun Technology has attracted customers from all over the world at previous exhibitions. The scene is very lively and is a beautiful scenery of the exhibition. At this Canton Fair, Aoqun Technology will bring a number of self-developed products to the show, including UL94-V0 flame retardant brushes, shielding door sealing brushes, escalator safety anti-pinch brushes and lintel sealing brushes, etc., showing Aoqun Technology's innovative strength and spirit of continuous exploration and progress on the road of independent research and development. Aoqun warmly welcomes you to visit the Aoqun Technology booth for guidance and to discuss cooperation. -Invitation Letter-- Highlights preview 01 No deformation after 1 million high-frequency frictions This patented product[high elastic wear-resistant flame-retardant sealing brush] can achieve 1 million high-frequency frictions without deformation. It has passed the European rail vehicle fire protection standard EN45545 test, Bombardier fire smoke test, and UL94-V0 flame retardant test, and complies with more than 30 European and American industry standards. 02 Prevent 98.5% air leakage Aoqun Rail UL94-V0 flame retardant sealing brush can effectively prevent 98.5% air leakage. It has the effect of sealing and dustproofing, energy saving and noise reduction, and safety and flame retardancy in carriages, platforms, screen doors, escalators and other locations. 03 Application in multiple urban rail transit projects It has been widely used in rail transit projects in more than 50 countries and regions around the world and 80% of key cities in China, such as the door sealing brushes and escalator safety anti-pinch brushes in multiple high-speed rail and subway lines in the Guangdong-Hong Kong-Macao Greater Bay Area, creating a comfortable riding experience for passengers and making every trip more pleasant and safer. About Aoqun Technology Aoqun Technology has been focusing on the research, production, supply and marketing of high-quality brushes for 20 years, and has been awarded the title of National High-tech and Provincial Specialized New Enterprise; it is committed to providing customers with a full range of full-scene, high-performance, high-precision one-stop high-end brush solutions, and has provided high-quality brush mass customization and related supporting products for more than 30 leading companies in industries such as high-speed r...

read more

On the 55th World Earth Day in 2024, the theme is "Global Fight Plastic," calling on people to resist the overuse of plastic products protect the Earth's environment from pollution. AOQUN Technology has always been in action to make the blue planet more beautiful. New patented high-performance brushes: ZL202210598941.4 ZL202210574951.4 ... Reducing environmental pollution to bring new vitality to the blue planet. Actively exploring environmentally friendly alternatives committed to manufacturing green technology products such as bio-based environmentally friendly brushes, biodegradable brushes, and plastic recycling. Promoting resource recycling to contribute to creating a green Earth together. Green sustainable development is the continuous effort of AOQUN Technology. Let's take action together to relieve the Earth's pressure Brush towards a beautiful, sustainable future!

read more

The 135th Canton Fair Phase II, themed "Quality Home", will kick off grandly on April 23rd. As the comprehensive exhibition representative enterprise of Nansha District, AOQUN Technology will showcase a variety of new and advanced intelligent brush products at the Canton Fair. We aim to enhance the brand image of Nansha, focusing on technological innovation in brush production, and enjoy a high-quality and intelligent lifestyle. Various new types of brushes showcase their specialties Precision polishing, a selection of ingenuity The new wear-resistant industrial brush significantly improves the removal of burrs in key processes of intelligent home manufacturing, with a removal rate increase of up to 2 times, and a product yield of over 99.96%. It solves the "bottleneck" problem of low polishing yield for screens and glass in 3C digital products on the market, injecting new vitality into the excellent quality and sustainable development of high-end manufacturing industries. Intelligent manufacturing, leading innovation The new high-end intelligent electric toothbrush for 3C innovation in materials, cleaning effects, intelligent functions, energy conservation and environmental protection, user-friendly design, charging technology, and user experience. AOQUN Technology has established long-term cooperation relationships with many leading companies in the appliance industry. Technological breakthroughs, cutting-edge new materials The new ultra-elastic, high-temperature-resistant PEEK electronic cigarette brush is strictly produced in accordance with international production standards, quality control systems, advanced automated production equipment, and technological production. After precise tests such as high-temperature resistance and plug-and-pull, it achieves a CPK value of ≥1.67, withstands temperatures above 280°C, and does not melt for 20 seconds of contact. The brush does not shed after 3000 plug-and-pull tests, ensuring the mass intelligent production of high-quality electronic cigarette brushes. Efficient cleaning, safeguarding health The new antibacterial health care medical brush meets FDA, CE, and antibacterial standards in more than 30 international medical industry standards. With a capacity of 200 million units per year, it sells in more than 2000 hospitals worldwide, providing support for the health and medical fields. Welcoming guests from all over the world Focusing on the research and development innovation of new high-quality brushes, AOQUN Technology has a research and development center and has obtained 50 patents for inventions and utility models reaching the international advanced level. It has passed 7 management system certifications including ISO9001, ISO13485, and IATF16949 and is a core supplier of 20 Fortune 500 companies. We warmly welcome guests from Europe, America, and countries along the Belt and Road to strengthen trade cooperation and contacts, providing customers with more accurate and suitable one-stop customi...

read more

With the rapid development of society and the continuous innovation and progress of human beings, food and agricultural by-product processing has replaced the artificial era, and fruit and vegetable cleaning machines are chosen, which can clean and peel fruits and vegetables. The main accessory is the brush roller. The interior of the fruit and vegetable cleaning machine is composed of brush rollers. After the food is used, it is pushed into the fruit and vegetable cleaning machine by the spiral brush, and then the food is cleaned by the spray head. Usually, the hardness of the hair of the brush roller is changed according to the number of times of use. If you choose a brush roller with high hardness, you can achieve the peeling effect of root fruits and vegetables. If the brush roller with soft hairs can achieve the effect of polishing fruits and vegetables, some equipment only use sponge rollers to clean fruits and vegetables. Finally, it can absorb water. Of course, the brush roller mentioned here has higher technical requirements than the brush roller in general industry. The shaft of the brush roller is made of stainless steel SUS304, and the brush is made of nylon wire, and the brush roller is made according to the requirements of food hygiene. Therefore, the application of brushes can be shown in many industries. Aoqun Brush Factory is a professional manufacturer of customized brushes. You can choose the appropriate brushes to apply to your industry, or our engineers will follow what you said. Request to make to order.

read morescan to wechat

scan to wechat