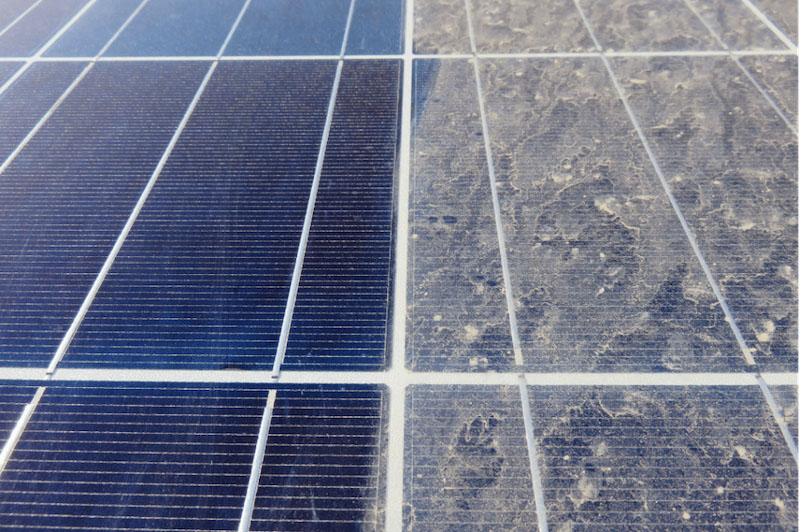

After the photovoltaic system is installed, the user is most concerned about the power generation, because it is directly related to the user's return on investment. There are many factors that affect the power generation, such as the quality of components, inverters, cables, installation orientation azimuth, inclination angle, dust, shadow occlusion, system scheme for component and inverter ratio, line design, construction, grid voltage, etc. factors are possible. The most common types of pollution solar photovoltaic panels are the following: Components affected by dust. The dust on the surface of the panel has the functions of reflecting, scattering and absorbing solar radiation, which can reduce the transmittance of the sun, resulting in a decrease in the solar radiation received by the panel and a decrease in output power. 1. The influence of temperature, with the accumulation of dust on the surface of the module, the heat transfer resistance of the photovoltaic module is increased, and it becomes the heat insulation layer on the photovoltaic module, which affects its heat dissipation. 2. Blocking effect, dust adheres to the surface of the battery panel, which will block the light, absorb and reflect the light. Compared with the dusty components, the output power of the clean battery panel components is at least 5% higher. 3. The surface of photovoltaic panels is mostly made of glass. When wet acidic or alkaline dust is attached to the surface of the glass cover, the glass surface will be slowly eroded. Photovoltaic panels are very fragile and cannot be cleaned with hard objects. They cannot be stepped on solar panels, brackets and other parts. They are easy to damage the power station and affect the service life. Therefore, use a fully automatic cleaning machine equipped with solar panel cleaning brushes. , is the best cleaning tool. The solar cleaning brush installed in the cleaning machine is made of thousands of filaments, which will not damage the solar photovoltaic panels.

read more

One of the leading and reliable sources of energy is solar energy. It has become very popular and as the demand for this industry is growing. Some of the reasons why it is good to go for solar include low maintenance cost, does not require much space to function, pollution-free and they can work on their own. Every building with roofs will have the opportunity to install solar panels to produce power and reduce carbon emissions. After the panels have been installed, they usually require little maintenance to function. In order to make the most out of the investment, it is important to make sure that the solar panels function at their best to maximize energy savings. Is It Necessary To Clean Solar Panels? Generally, most solar panels are self-clean as they are installed at an angle so rainfalls can give the panels a good washing. On the other hand, if the area where the panels are installed does not receive a lot of rain or if they are installed near factories, airports, the coast or highways, regular cleaning is important because these places generate more dust and dirt. Bird droppings or stubborn dirt can obstruct sunlight and this will affect the performance of the solar panel systems. Cleaning the solar panels is pivotal for them to function at their optimal capacity all year round. Increase Efficiency Solar panels that are clean will deliver a much higher energy strength than uncleaned panels. When dirt, dust and bird droppings accumulate on the panel glass, they will decrease the amount of sunlight being absorbed. When they are not receiving enough sunlight, the solar panels will not be able to perform at maximum capacity. This may lead to an increase in cost when the system has to rely on the grid to make up for the panels’ inefficiency. Solar PV Panel Cleaning Brushes Protecting Investment Solar panels are a big investment. Regular cleaning of the solar panel system with the right photovoltaic panel cleaning brushes will help to extend its lifespan and improve efficiency in producing electricity. Taking care of the panels to ensure that they are clean will not only help them to increase productivity but also ensure that they do not degrade faster than they should. Ultimately, regular cleaning using high-quality cleaning brushes from Aoqun, a leading solar panel cleaning brushes manufacturer will ensure the most return on the investment. Debris and dirt are unavoidable threats to the production of solar energy, especially for solar plants located in dusty areas. This can cost millions of dollars to be lost. Therefore, it should be the main priority for providers to minimize overall costs and maximize efficiency by cleaning the panels regularly.

read more

Photovoltaic power generation is a technology that directly converts light energy into electrical energy using the photovoltaic effect of the semiconductor interface. It is mainly composed of three parts: solar panels (components), controllers and inverters. The main components are composed of electronic components. After the solar cells are connected in series, they can be packaged and protected to form a large-area solar cell module, and then combined with power controllers and other components to form a photovoltaic power generation device. Use a special photovoltaic panel cleaning brush to clean. At present, most of the large photovoltaic panels are built in the northwest region of my country. The northwest region is sparsely populated and rich in land resources. The terrain is relatively higher than the south, and the light resources are abundant. The environment I want to compare is relatively harsh, and the wind, sand and dust are more obvious. Therefore, the photovoltaic panels should be cleaned regularly so that the normal use of the photovoltaic panel components will not be affected, and the photovoltaic panel cleaning brush is the hero behind the scenes. The photovoltaic panel cleaning brush is made of pure nylon wool, which has good flexibility, strong recovery, wear resistance, and will not scratch the expensive photovoltaic panel component equipment. normal life of the board. Moreover, it can be suitable for various mechanical or customized brush sizes of cleaning equipment factories, and the adaptability is very strong. Such a photovoltaic panel cleaning brush can be customized for you in Guangzhou Aoqun Brush Technology Co., Ltd., and a design and production team with 13 years of industry experience can provide you with reasonable and effective project solutions to solve your photovoltaic panel cleaning brush design, installation problems.

read more

As there is a mounting concern across the globe to protect the environment, many countries have been or are open to the idea of installing solar panels in their areas to generate their own electricity. Solar panels, also known as photovoltaics (PV) harness the sun's energy using photovoltaic cells and then convert it into electricity. They are a great way to reduce energy costs and also the dependence on fossil fuel which in turn, reduces the environmental impact of the house. Solar Photovoltaic Panel Do you know that the solar panel can still draw energy even on a cloudy day? Of course, more solar energy can be produced on a sunny day but even on a cloudy day, it can produce around 10 to 20 percent of the power generated on a usual sunny day. Solar panels are installed on rooftops between layers of semiconducting material such as silicon. When the sunlight shines on them, the electrons will create a flow of electricity. If you have installed solar panels in your home, you would need to keep them clean. In order to generate more power, more light has to hit a panel. The angle of the solar panels on the roof makes them more prone to dust, dirt, leaves, and not to mention birds droppings. All these build-ups cannot be washed off by rainwater and may reduce the amount of light hitting on the panel. This will have an adverse impact on the performance of the solar panels. It is important to clean the solar panels so that they can improve their efficiency and produce maximum electricity. Solar Panel Photovoltaic Cleaning Brush What Is A Solar Panel Cleaning Rotating Brush? Made with soft nylon filament, this brush features a stainless steel base and fastening wire that are wound on the central axis. The rotating solar panel brush is attached to a pressure washer to power it. This can save a huge amount of time in the cleaning process and also clean the panels effectively compared to the traditional fixed brushes. The longer the brush diameter, the more areas it can clean in one go. Besides solar panels, this specially designed rotating brush can be mounted onto the cleaning machine to clean exterior walls, billboards and glass roofs, and more. The size of the brush can be customized according to your requirements. Solar Panel Cleaning Rotary Brushes How To Clean The Solar Panels? For the power plant, it is vital that you wash the panels with care. You do not want to scratch them with an abrasive sponge or strong chemicals. The best way to clean the panels is to approach them the same way you would clean your car. You can purchase good-quality solar photovoltaic panel cleaning brushes from AOQUN, a leading large-scale brush manufacturer with over 20 years of experience in brush production. One of the best brushes for cleaning solar panels is the Reusable Cleaning Rotating Brush. For the best solar panel cleaning brushes that will help you to improve quality and productivity, head over to Aoqun Brush Factory .

read more

The solar photovoltaic panel cleaning brush can be designed into spiral brush rollers, flocking brush rollers, disc brushes, and other shapes according to the cleaning equipment. Solar photovoltaic cleaning brushes are widely used in ground photovoltaic power station cleaning, color steel tile factory roof photovoltaic power station cleaning, photovoltaic greenhouse cleaning, roof photovoltaic power station cleaning, and ground photovoltaic power station cleaning at different heights. Photovoltaic solar panels mainly rely on absorbing solar energy and converting it into electrical energy. Power generation, cleaning as required can ensure the cleanliness of the surface of the photovoltaic panel, which is conducive to absorbing as much sunlight as possible, thereby ensuring the power generation; if the modules accumulate dust for a long time, not only the power generation will be lost, but also a hot spot effect will occur, resulting in Component life is short and even damaged; therefore, it is necessary to constantly pay attention to the cleanliness of components, and clean them properly to ensure the power generation. The solar panel photovoltaic cleaning brush roller has always been a very friendly topic in recent years. With the rise of the solar photovoltaic industry, the demand of manufacturers for cleaning the solar brush roller has also greatly increased. The brush roller has been deeply used in the industry in the past. With the change of the brush, the brush roller is also constantly changing. The rise of brush rollers has also brought great results. Cleaning the photovoltaic panel brush in order to better keep the photovoltaic panel clean. The formation of brushes also contributes to the enhanced effect of photovoltaic panels. Better highlight the rise of photovoltaic panels in the field of brushes. The brush industry is also constantly changing. Solar Panel Photovoltaic Cleaning Brush In the past, the industrial brush with hair planting can better understand that the brush is in bundles, but now in order to better strengthen the change of the brush, the brush is carried out in a winding method. The installation of brushes has also been greatly changed. No matter how the brush is produced and manufactured, the brush roller is essentially the same material, but the processing method is different. There are pros and cons to the effect.

read more

The global automobile manufacturing industry is advancing by leaps and bounds, changing with each passing day, especially the overall level of the auto parts industry is developing rapidly. The technical quality requirements of auto parts are also gradually improved. As an important indicator affecting the quality and reliability of auto products, cleanliness has attracted people's attention. During the processing process, the impurities attached to the surface of the parts will affect the fine stamping process. The surface quality of the parts will be affected, and the shape accuracy of the parts will be affected, resulting in complex grinding after stamping, and in serious cases, it will be scrapped. Therefore, in order to ensure cleanliness, auto parts must undergo a strict cleaning process between the processes before processing, and the cleaning equipment includes the use of brush rollers. Brush roller As one of the factors affecting the surface quality, the cleaning machine equipment, after long-term production loss, the cleanliness of the blanks deteriorates year by year. Even if many possibilities of cleaning problems for the blanks can be gradually eliminated, the effect is not ideal, so the equipment is put into production. From then on, attention must be paid to the guide roller, brush roller, and squeeze roller of the cleaning machine during PM maintenance. The quality of the blade when the uncoiler is formed directly affects the number of burrs on the edge of the material. If the uncoiler cutter is dull, there will be more burrs on the edge of the material. Since the guide roller is made of polyurethane, before entering the punching line for punching The polyurethane on the surface of the guide roller will be damaged during cleaning, that is to say, when the equipment is put into production, the polyurethane on the surface of the guide roller may be damaged by the material with a large burr, so the advanced cleaning machine has high requirements for the burr of the material. , the control of burrs in actual production cannot be done well. The utility model relates to a high-speed line cleaning machine. The function of the cleaning machine in the high-speed press line is to clean up the oil stains and impurities on the surface of the board before pressing the board. The main components are a pair of polyurethane guide rollers, brush rollers, cleaning liquid nozzles, squeeze rollers, and so on. The plate is first entered by the polyurethane guide roller, and then the oil stains on the surface of the plate are washed off under the action of the cleaning liquid and the brush roller, and then the whole cleaning work is completed after being squeezed by the squeeze roller, and the next process is entered.

read morescan to wechat

scan to wechat